instrument to perform a compressive and tensile test|tensile tester manual : convenience store Regarding testing material factors of PEM ® self-clinching fasteners, our engineers call upon two key testing methods: push-out testing (a variation of a compression test) and tensile testing. These two methods work hand in . webBonds Australia Promo Code: $20 off clothing, underwear, and more. $20 Off. Expired. Apply this Bonds free shipping code for your next purchase. Free Shipping. Expired. Bonds discount code for 10% .

{plog:ftitle_list}

Resultado da I am in a constant search for risk.I encourage you to follow your dreams and reach your maximum potential through discomfort and i commit to doing .

tensile testing tools

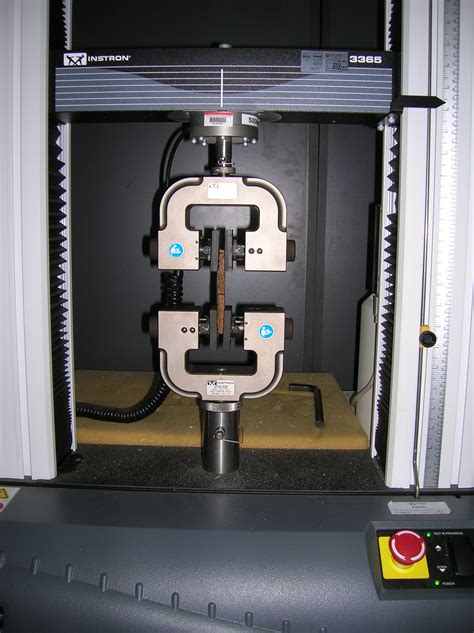

A tensile tester, also known as a pull tester or univeral testing machine (UTM), is an electromechanical test system that applies a tensile (pull) force to a material to determine the .Instron manufactures tensile, compression, fatigue, impact, rheology, and structural testing machines, testing a variety of materials and range of applications. Telephone: +1 800 877 6674.Instron's 6800 Series systems are available in capacity ranges up to 300 kN and can perform a wide range of different test types, including tensile, compression, bend, peel, tear, shear, .

A tensile test is used to determine the yield point or yield strength, tensile strength or ultimate tensile stress, and percentage elongation of a metal. The tensile Testing method measures the force required to break a metallic, .Regarding testing material factors of PEM ® self-clinching fasteners, our engineers call upon two key testing methods: push-out testing (a variation of a compression test) and tensile testing. These two methods work hand in .

Yarn Strength Tester store

6. The importance of performing a compression test. You can perform compression testing at multiple stages of production to determine the authenticity and safety of materials, parts, and products. From strength . Tensile testing and compression testing are both crucial in determining a material’s ability to withstand real-world conditions it’s designed for. A compression test is a common method used in this process, and multiple compression tests can provide even more insight into a material’s strength and durability.

Brookfield CT-3 Texture Analyzer is a powerful universal testing machine that offers both compression and tensile testing for food and low strength polymers. . Source: MTI Instruments In advanced tensile testing, the impact of environmental conditions and temperature on tensile properties is evaluated. A polymer's tensile "static" properties . In addition, the vulcanized rubber mechanical properties test results for the compression set parameter increased between 28.6% and 57.1%. Scan results with SEM–EDS showed that using ZS could .The Universal Testing Machine or the UTM is dual-testing machine can perform compression and tensile testing. The Universal testing machine enables measurement of firmness and harness. It is based on a physical property called the indentation force deflection (IFD).

Experiment One –Tensile Stress Test The tensile testing machine consists of an electro-mechanical test system that applies uniaxial loading in a uniform manner to test specimens. It is general purpose in its capabilities and applications. The system performs load versus elongation (stress versus strain) tests which Similarly, when using the maturity method on your jobsite to test compressive strength, it is recommended to perform cylinder break tests on day-28 of your concrete’s lifecycle for acceptance . The 50 kN capacity and the fully variable test speed of 0.2 to 51 mm/min make it possible to perform not only the CBR and Marshall tests, but many other applications as for instance Indirect Tensile test, Quick Triaxial tests, Unconfined and Uniaxial soil testing and, in general, all test to be performed under displacement control. Compression tests of a polymer structural foam material is covered by ASTM D1621 which specifies the type of compression plates and deflectometer used. The test sample is placed between compression test platens until the cellular structure fails or ruptures. A universal test machine can perform either or both tension and compression tests.

Video 1: Tensile testing of annealed Cu sample (video and evolving nominal stress-strain plot) This page titled 5.5: Tensile Testing - Practical Basics is shared under a CC BY-NC-SA license and was authored, remixed, and/or curated by Dissemination of IT for the Promotion of Materials Science (DoITPoMS) via source content that was edited to the .

These fundamental parameters include the elastic limit, which for "Hookean" materials is approximately equal to the proportional limit, and also known as yield point or yield strength, Young's Modulus (these, although mostly associated with tensile testing, may have compressive analogs) and compressive strength.Compression testing is one of the most fundamental types of mechanical testing, alongside tensile and flexion tests. Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using platens or specialized .Tensile testing can also be used to verify that materials adhere to minimum strength and elongation requirements. From suspension bridge cables to safety harnesses, lives may depend on the quality of your materials and products so .The Universal Testing Machine (UTM), also known as a Universal Tester, Materials Testing Machine, or Tensile Testing Machine, is a versatile piece of equipment that can perform multiple types of mechanical tests, including .

Compressive strength testing of concrete:-The test is carried out using 150mm concrete cubes on a Universal testing machine or compressive testing machine. Apparatus. As per IS: 516-1959 Compressive testing machine (2000Kn),15cm×15cm×15cm steel cube molds or Cylinder having Dia 15cm and length 30cm are used. The test includes following steps:- Issues with Compressive Testing. There are potential sources of complication with both tensile and compressive testing. A major issue with tensile testing is the onset and development of “necks” (regions of strain concentration). This is covered as a separate topic (“Necking & the Ultimate Tensile Strength”). A compression test is an important test to understand how a material will behave during metalworking. Many operations during metalworking are performed by applying compression loads, for example: rolling , forging , extrusion , etc. Compression tests are also useful to determine the properties of some materials that can not withstand tension .

Leading Compressive Strength Instruments. We have a wide selection of compressive testing equipment. This includes products such a Box Compression Testers, Single Column Tensile Testers, Crush Testers, Sample Cutters, Universal Testing Machines, Hydraulic Testing Machines, Environmental Chambers and Thermal Chambers.Typical lectromechanical Universal Testing Machine Test fixture for three point flex test. A universal testing machine (UTM), also known as a universal tester, [1] universal tensile machine, materials testing machine, materials test frame, is used to test the tensile strength (pulling) and compressive strength (pushing), flexural strength, bending, shear, hardness, .

tensile testing system

tensile testing software

• Commonly used to perform tensile, compression, peel, and bend tests on medical devices, biomaterials, microelectronics, elastomers, plastics, films, and textiles . offers the highest level of load cells apart from the competition.flexibility in a testing instrument. Designed for Safety Safety is at the core of 5900 systems. A host of safety

Tensile testing is arguably the most common test method used in both force measurement and material testing. Tensile testing is used primarily to determine the mechanical behavior of a component, part or material under static, axial loading. The test method for both material testing and force measurement is similar; however the measurement results are .Universal Testing Systems for Tensile, Compression, and Flexure Testing. The NEXT GENERATION 6800 Series universal testing systems range in capacity from 500 N to 300 kN and provide exceptional performance with unparalleled accuracy and reliability. Offering up to 5 kHz data acquisition and 0.5% accuracy down to 1/1000th of load cell capacity .A tensile test can be performed on a Materials Testing instrument or Texture Analyser which are force measuring instruments that perform compression and tensile tests and provide an objective quantification of compressive or tensile strength. Tensile strength is the maximum force (or stress) that can be applied before it breaks or fails or .1.3.2. On Test Control > Pre-Test, enable Preload and apply a small preload to ensure that there is no slack in the specimen. Preload value should be lower than preload used in method used to test specimens. 1.3.3. On Test Control > End of Test, set the end of test criteria to a force higher than expected in a real test, but lower

Tensile test: Tensile strength, yield strength/offset yield, strain at break, reduction of area: Machined test pieces: 9.8: Head soundness test: Head strength: Bolts and screws: 9.9: Hardness testing: Hardness to Vickers, Brinell or Rockwell: All bolts and screws, in particular those which are too small for a tensile test: 9.10: Decarburization .

UNIVERSAL TENSILE TESTER store

Resultado da Siga a Aldes no TikTok. Nos faça uma visita. Fale conosco. Create your Linktree. O upgrade que seu lar merece | Montagem e entrega grátis no RJ.

instrument to perform a compressive and tensile test|tensile tester manual